Details

| Laser power | 50w/60W/80w/100w | |||

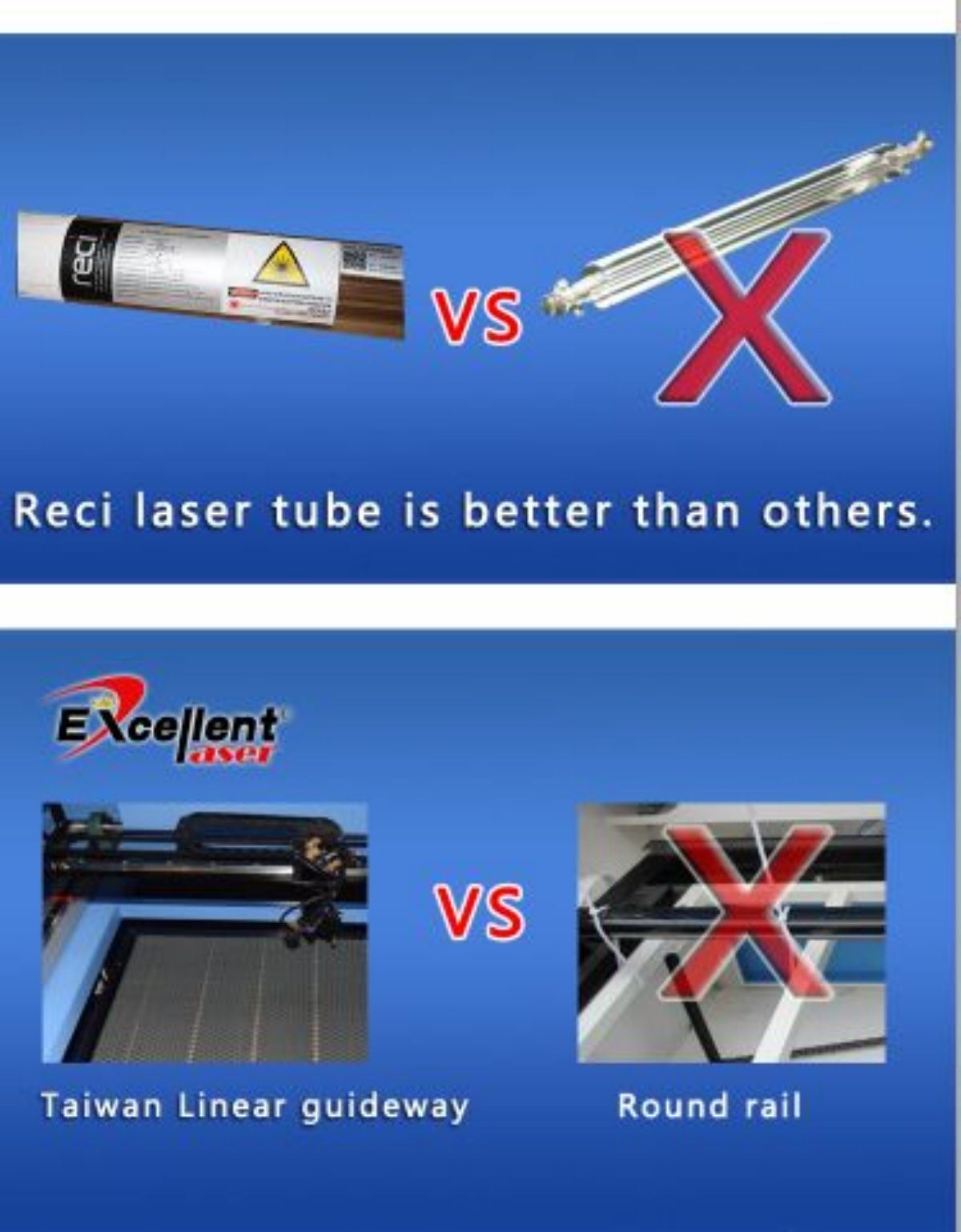

| Laser type | Hermetic Co2 glass tube | |||

| Power supply | AC220±10% 50H2/AC110±10% 60HZ | |||

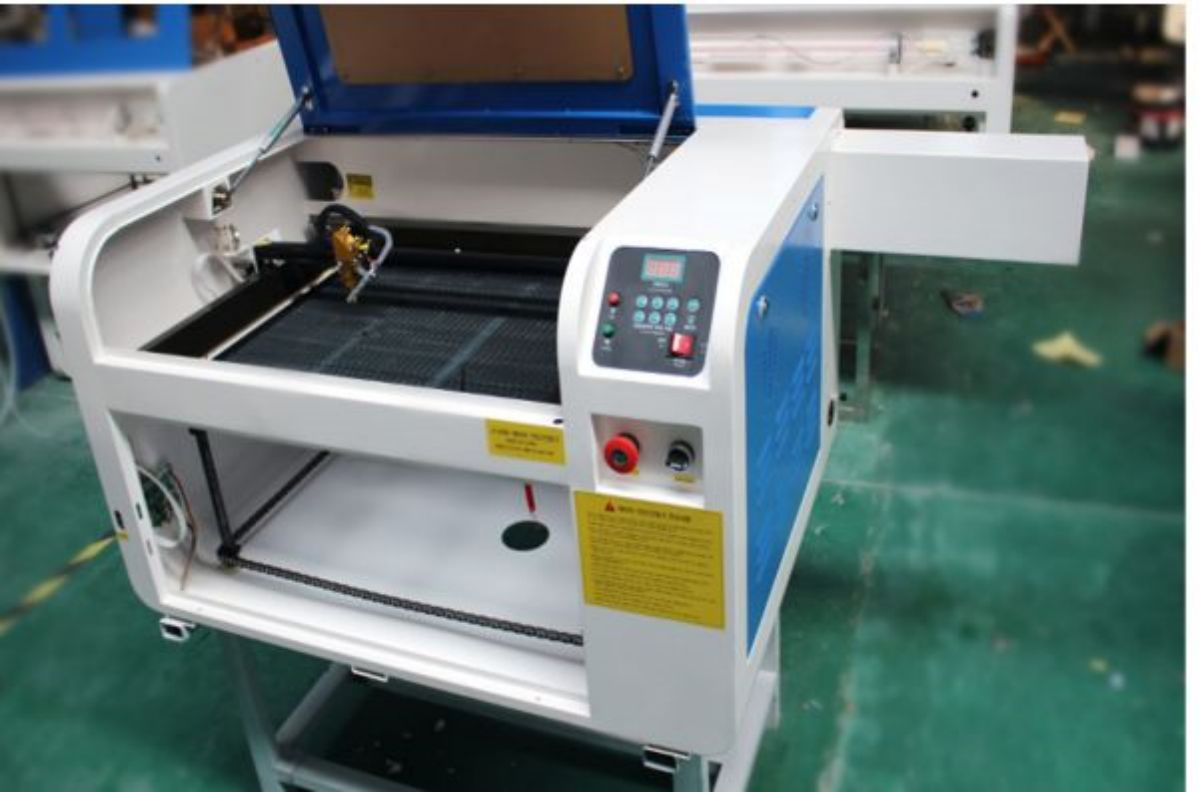

| Work Area | 400X600mm | |||

| Max Moving Speed | 0-60000mm/min | |||

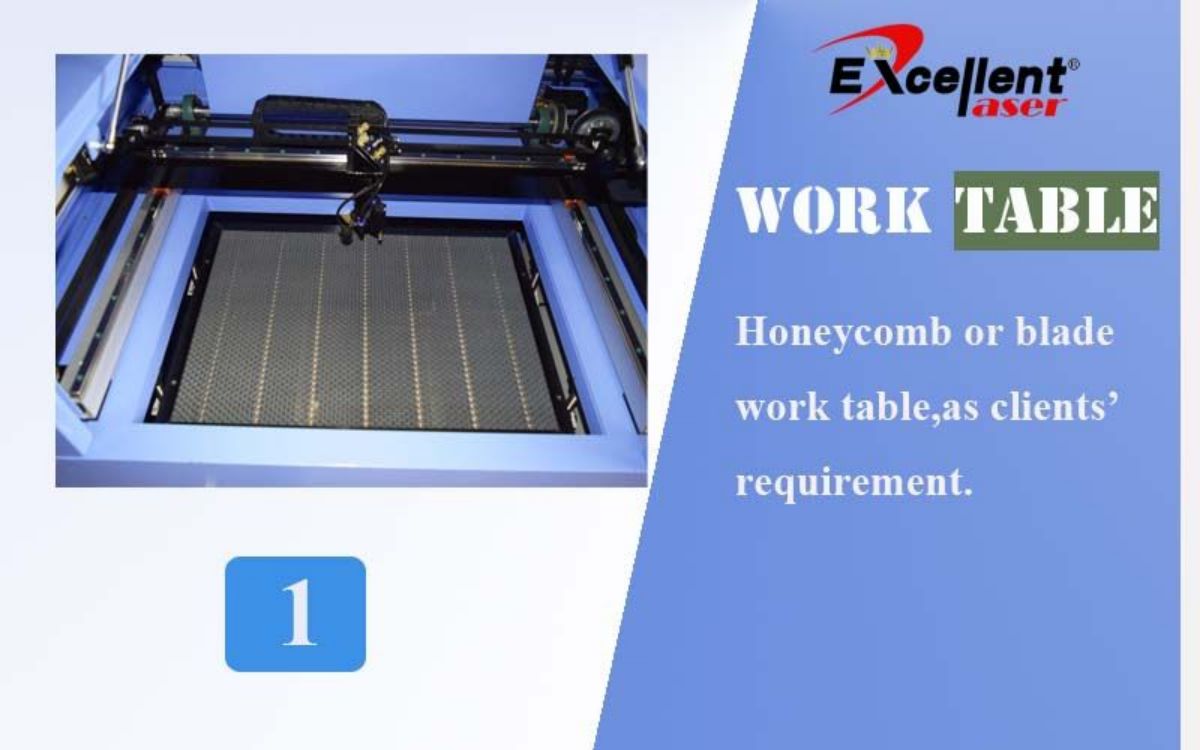

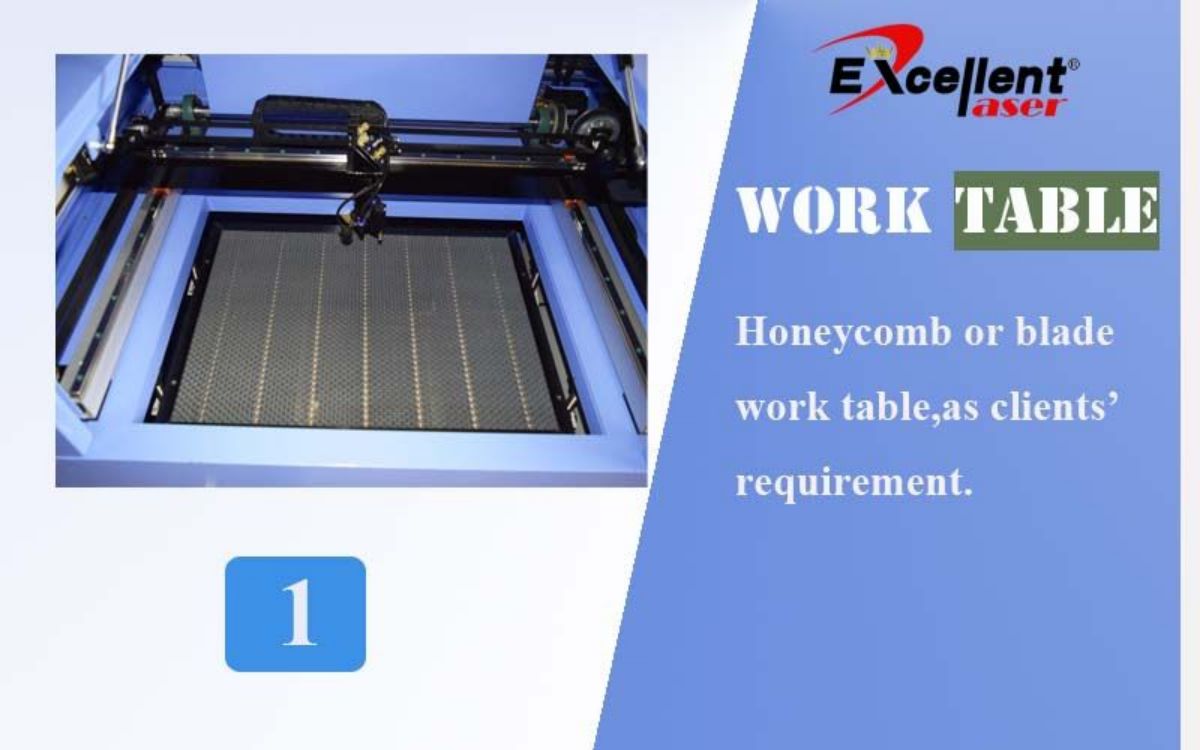

| Work table | up and down table | |||

| Locating Precision | 0.01mm | |||

| Min Shaping Character | Character 2x2mm Letter 1x 1mm | |||

| Operating Temperature | 5℃-35℃ | |||

| Resolution ratio | ≤4500dpi | |||

| Control Configuration | DSP | |||

| Data transfer Interface | USB(office) | |||

| System Environment | WINDOWS 2000/ WINDOWS XP/Visa/Win7 | |||

| Cooling Way | Water Cooling | |||

| Graphic Format Supported | BMP.GIFJPGE.PCX.TGA.TlFF.PLT.CDR. DMG.DXF.PAT.CDT.CLK.DEX.CSL.CMX.WF | |||

| Compatible Software | CorelDraw.AutoCAD | |||

| Cutting Thickness | 0-10mm(depends on different material) | |||

| Color Separation | Separation of cutting up to 256 colors | |||

| Sloping Engraving | Yes,slope can be designed discretionanly | |||

| Cuts off the water supply the protection | Yes | |||

Advantages of CO2 laser engraving

1. Wide range: carbon dioxide laser can carve and cut almost any non-metallic material. And the price is low! 2. Safe and reliable: non-contact processing will not cause mechanical extrusion or mechanical stress to materials. No "knife mark", no damage to the surface of the work piece; no deformation of the material; 3. Precision and delicacy: the machining accuracy can reach 0.02mm; 4. Saving environmental protection: the diameter of light beam and spot is small, generally less than 0.5mm; cutting and processing saves materials, safety and health; 5. Consistent effect: ensure that the processing effect of the same batch is completely consistent. 6. High speed and fast: high speed carving and cutting can be carried out immediately according to the drawings output by the computer.Other type picture

Application

For industry, Advertising, arts and crafts, leather, toys, clothing, model, building upholster, computerized embroidery and clipping, packaging and paper industry Application materials Wood, bamboo, jade, marble, glass, crystal, plastic, clothing, paper, leather, rubber, ceramics, glass and other non-metallic materials.Company Information

Payment Term

Shipping and Package

After-sale Service